FOURESS PRODUCTS IN THERMAL POWER PLANTS (COAL FIRED AND GAS FIRED)

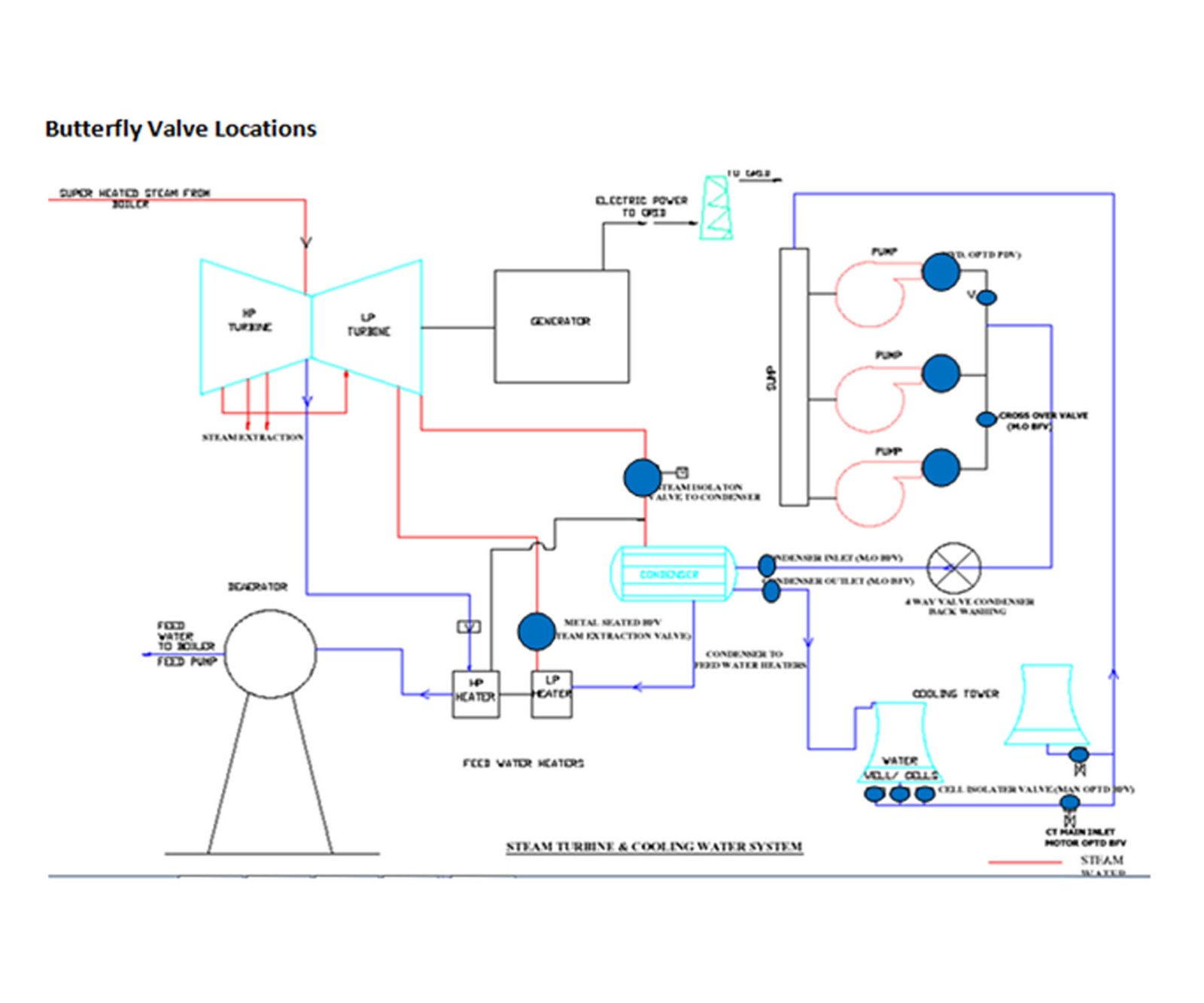

Valves suited for applications in the power generation industry include triple offset, high performance butterfly valves, double eccentric butterfly valves, and resilient seated concentric butterfly valves.

Fouress double eccentric butterfly valve finds application in Circulating Cooling water lines for Isolation as well as a special application as a Pump Discharge Valves at the discharge of Large Circulating Water Pumps. The Fouress Design of Pump Discharge Valve with Hydraulic actuation , allows the user to eliminate the Pump Discharge Check Valve.

The triple offset valve offers bi-directional gas tightness, innovative self-centering, flexible disc sealing. The design flexibility allows for ease of use in customized solutions. Thermal power plants require Fouress triple offset butterfly valves because they can withstand the high-pressure levels and the extremely high temperatures the materials subject them to. Since they are completely fire-proof, they’re also the safest option for Gas lines in Gas based Power Plants

The high performance butterfly valve offers a soft or metal seated design, is unparalleled in vacuum-to-low pressure environments, and is fire safe. It Flue gas desulphurization requires specialty valves such as slurry service isolation valves, an application that is met by Fouress Knife Gate Valves

Fouress Dampers in a coal fired Power Plant are located all the way from the induced draft fan and the primary air system to the flue gas scrubber outlets. Since several equipment such as fans and precipitators, are often paralleled, the number of installed dampers can be much higher than that operating Dampers. Fouress Dampers are installed in various locations of the Power plant as shown by the symbol .

Fouress Control dampers will be of the Opposed louver type, and Isolation dampers can be either Parallel Louver or Guillotine. Fouress recommends Louvre Dampers , if the damper must open or close quickly.. Fouress has also supplied Butterfly dampers for circular ducts adjacent to flue gas desulfurization systems.

The largest of Fouress Dampers are found in the FGD plants as Bypass Dampers which are usually Louvre Dampers ( as Quick Opening and Closing is required) .and as Booster Fan inlet and Outlet Dampers which are usually Guillotine dampers At the inlet to centrifugal fans, Fouress has also supplied parallel blade louver dampers. These damper types impart whirl to inlet air when damper vanes are partly closed, reducing power need.

Service conditions vary widely through the Power Plant . Clean low temperature air at the forced draft fan inlet contrasts with ash laden, wet, corrosive gas before or after the scrubber. Temperature changes of nearly 180 Deg C can occur suddenly when an air heater fails.. Fouress Dampers are designed to operate in these diverse conditions.